In this tutorial, we will create a mobile manipulator using a wheeled robot base and a robotic arm. All we need to do is to connect the arm_base link of the robot arm to the base_link of the robot.

This tutorial would not have been possible without Ramkumar Gandhinathan and Lentin Joseph’s awesome book ROS Robotics Projects Second Edition (Disclosure: As an Amazon Associate I earn from qualifying purchases). I highly recommend it if you want to learn ROS 1. Many of the files (URDF, configuration, and STL files), come from their book’s public GitHub page.

Real-World Applications

This project has a number of real-world applications:

- Indoor Delivery Robots

- Order Fulfillment

- Factories

- Warehouses

- Space Exploration

- Power Plants

Let’s get started!

Prerequisites

- You have completed this tutorial where you learned how to create a mobile robot base.

- You have completed this tutorial where you learned how to create a robotic arm.

Build the Mobile Manipulator

Open a new terminal window.

Move to the urdf folder of your package.

roscd mobile_manipulator_body/urdf/

Now create a file named mobile_manipulator.urdf.

gedit mobile_manipulator.urdf

Add the mobile_manipulator.urdf code inside there.

Save and close the file.

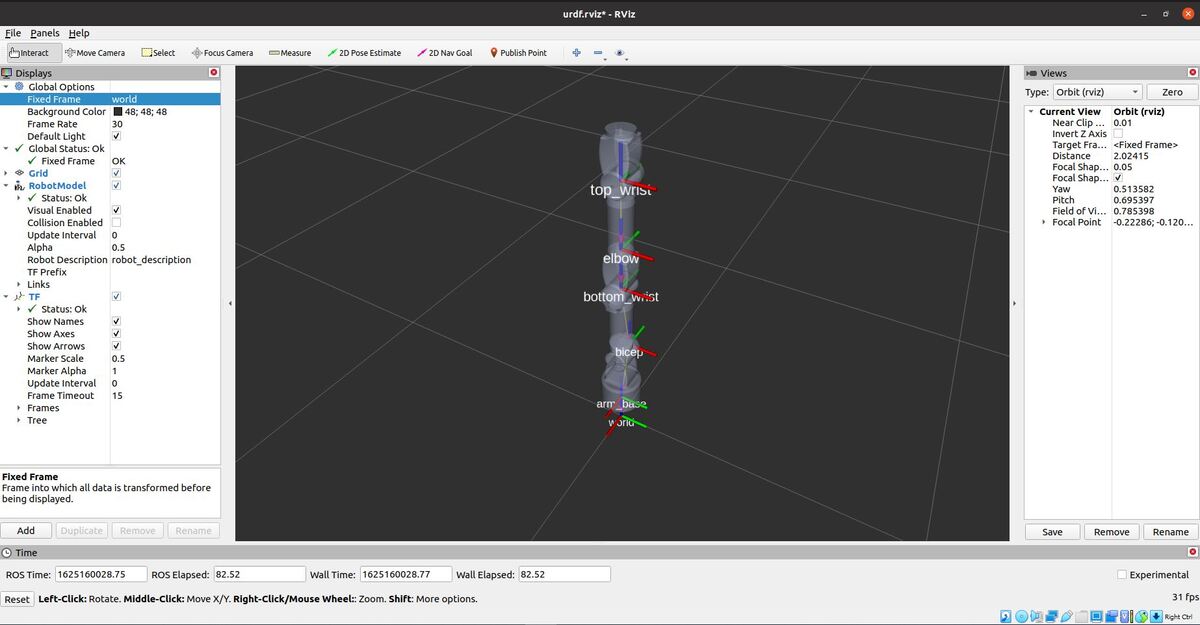

Test the Mobile Manipulator

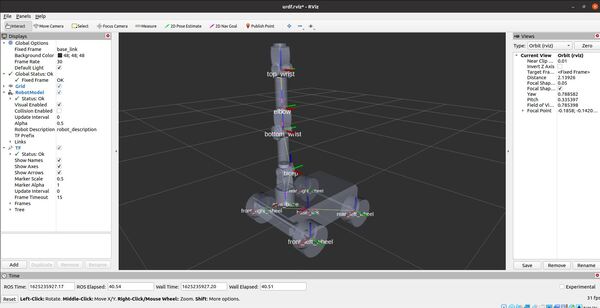

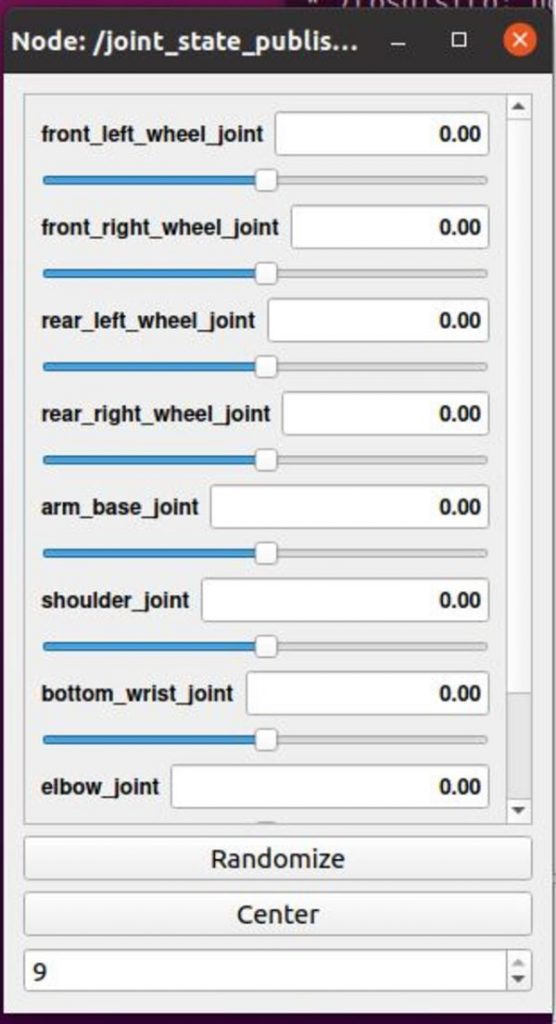

Now, let’s launch RViz to see what our robot looks like so far.

roscd mobile_manipulator_body/urdf/

roslaunch urdf_tutorial display.launch model:=mobile_manipulator.urdf

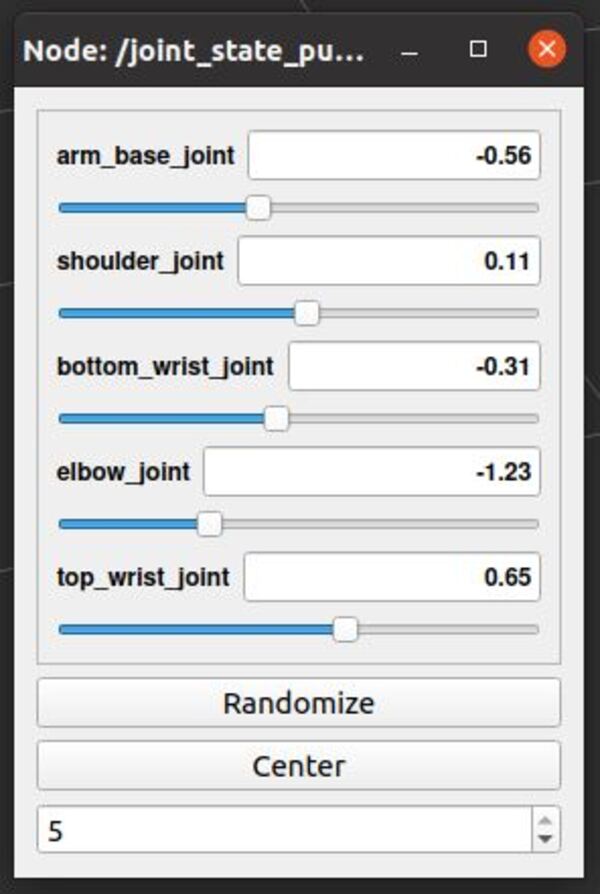

A GUI will appear that will enable you to move the joints.

Launch the Mobile Manipulator

Now let’s launch the mobile manipulator.

Open a new terminal window, and go to the package.

roscd mobile_manipulator_body/launch/

Create a new launch file.

gedit mobile_manipulator_gazebo.launch

Add the mobile_manipulator_gazebo.launch code inside there.

Save and close the file.

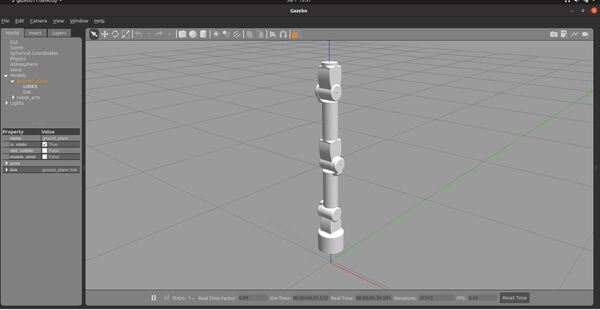

Now let’s launch the robot in Gazebo.

Move to your catkin workspace.

cd ~/catkin_ws/

roslaunch mobile_manipulator_body mobile_manipulator_gazebo.launch

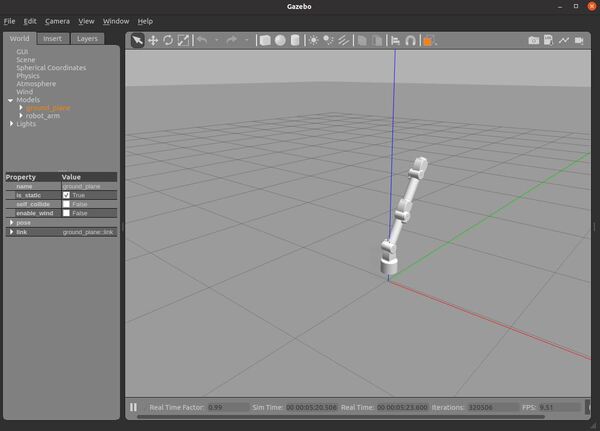

Here is how the robot looks.

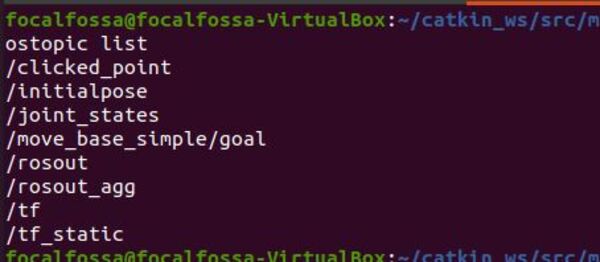

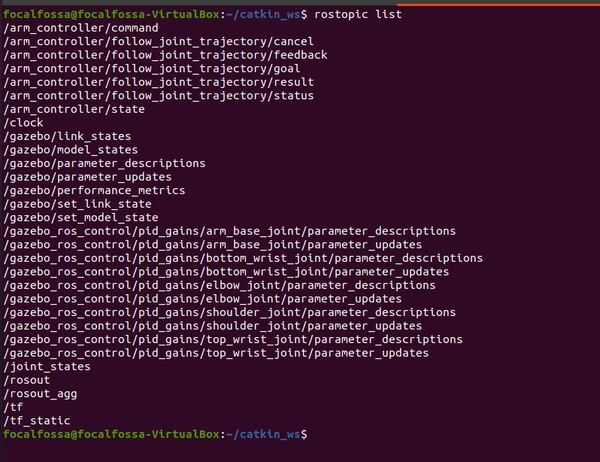

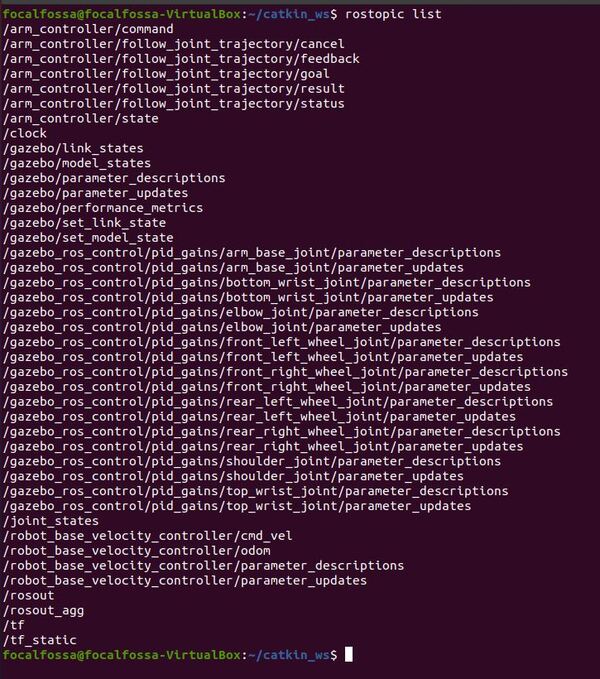

Here are the active ROS topics.

rostopic list

Open a new terminal, and type this command to move the robot arm a little bit:

rostopic pub /arm_controller/command trajectory_msgs/JointTrajectory '{joint_names: ["arm_base_joint","shoulder_joint", "bottom_wrist_joint", "elbow_joint","top_wrist_joint"], points: [{positions: [-0.1, 0.5, 0.02, 0, 0], time_from_start: [1,0]}]}' -1

Type this command to bring the robot back to the home position.

rostopic pub /arm_controller/command trajectory_msgs/JointTrajectory '{joint_names: ["arm_base_joint","shoulder_joint", "bottom_wrist_joint", "elbow_joint","top_wrist_joint"], points: [{positions: [0, 0, 0, 0, 0], time_from_start: [1,0]}]}' -1

You can steer the robot by opening a new window and typing:

rosrun rqt_robot_steering rqt_robot_steering

You will need to change the topic inside the GUI to:

/robot_base_velocity_controller/cmd_vel

To see the velocity messages, open a new window and type:

rostopic echo /robot_base_velocity_controller/cmd_vel