After I developed the source code, I converted the entire Python file (.py) into an executable (.exe file …. i.e. a program that can run on any machine) using a special software program called PyInstaller.

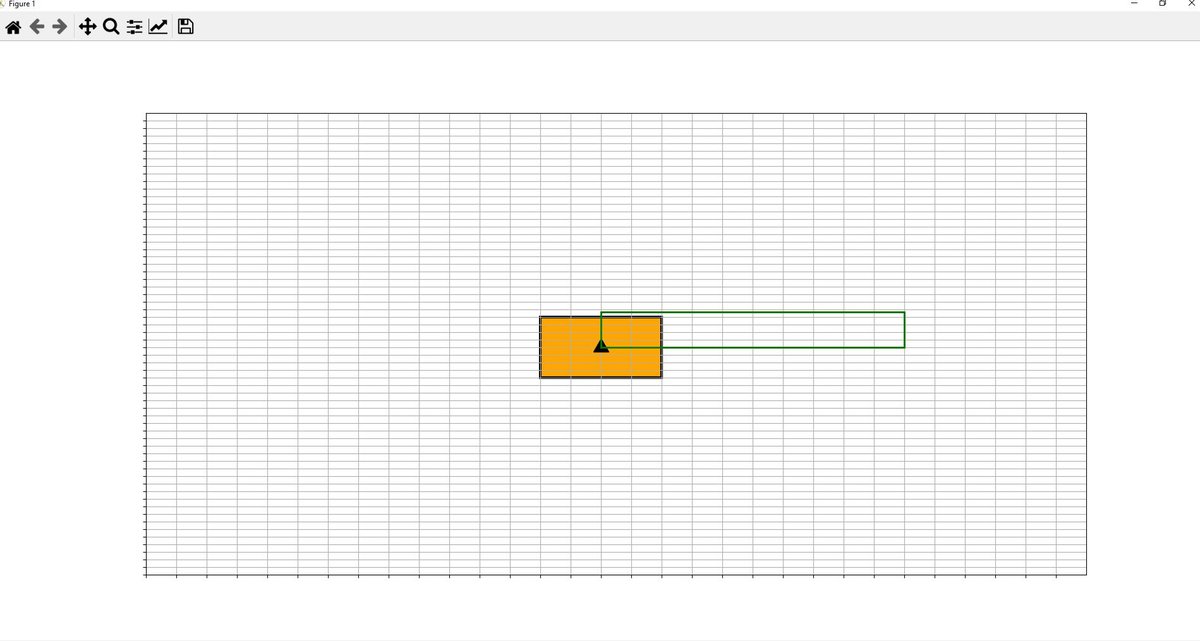

Calculate the interior angle in degrees between diagonal of rectangle and the side length

Converting local velocity in the robot frame to global velocity in the global (inertial reference frame)

Converting global velocity in the global (inertial reference frame) to local velocity in the robot frame

Convert direction (local) into direction (global) for the rectangle implementation

Other than that, you don’t need anything else to run the program. Just copy and paste this code into your favorite place to run Python programs, and off you go!

import math

import matplotlib.pyplot as plt

import matplotlib.patches as patches

import numpy as np

import time

import tkinter as tk

# Project: Omnidirectional Mecanum-Wheeled Robot

# Author: Addison Sears-Collins

# Date created: 02/22/2020

################### Initialize Constants ##################

# Set the robot vehicle's dimensions

# Robot is 2 feet in width and 4 feet in length

ROBOT_WIDTH = 2.0

ROBOT_LENGTH = 4.0

# Maximum speed of the robot in feet/second

MAX_SPEED = 15.0

# Robot vehicle's wheel radius in feet

WHEEL_RADIUS = 0.5

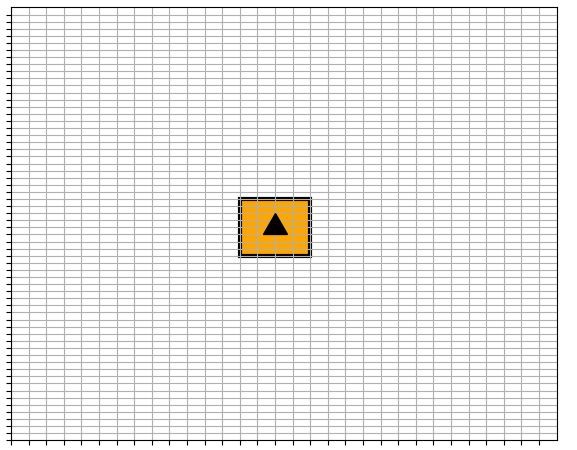

# Length and width of the viewable area on screen

# The grid is 30 feet long by 15 feet wide

ENV_LENGTH = 30.0

ENV_WIDTH = 15.0

# The distance between ticks on the x and y-axis in feet

# Each square on the grid is 6inch by 6inch

X_TICK_SPACING = 0.5

Y_TICK_SPACING = 0.5

# Boundary in feet. Viewable area will stay fixed until

# such time as the vehicle reference point travels within

# 3 feet of the viewable edge.

BOUNDARY = 3.0

################### Global Variables ######################

# The robot vehicle object (which will be a rectangle)

rect = None

# The coordinates of the vehicle reference point

x_pos_ref = None # in feet

y_pos_ref = None # in feet

vehicle_angle_ref = None # in degrees

# The grid specifications

x_axis_min = None

x_axis_max = None

y_axis_min = None

y_axis_max = None

# Store historical x and y-values in order to track

# the path traveled by the vehicle reference point

hist_x_vals = []

hist_y_vals = []

# The circle that pertains to the move_in_a_circle() method

# and the figure 8 method

circle1 = None

# The rectangle that pertains to the move_in_a_rectangle()

# method

this_rect = None

# Create a window using the Tk class

window = tk.Tk()

# Global flag

running_control_robot_body = False

running_control_robot_wheels = False

##################### Helper Methods ######################

def convert_local_velocity_to_global(v_x_local, v_y_local):

"""

Convert the velocities in the x and y-directions in

the local reference frame to velocities in the global

reference frame.

@param v_x_local float: Velocity in the x-direction

in the local reference frame in ft/s

@param v_y_local float: Velocity in the y-direction

in the local reference frame in ft/s

@return v_x_global float: Velocity in the x-direction

in the global reference frame in ft/s

@return v_y_global float: Velocity in the y-direction

in the global reference frame in ft/s

"""

v_x_global = (v_x_local * math.cos(math.radians(

vehicle_angle_ref))) - (v_y_local * math.sin(

math.radians(vehicle_angle_ref)))

v_y_global = (v_x_local * math.sin(math.radians(

vehicle_angle_ref))) + (v_y_local * math.cos(

math.radians(vehicle_angle_ref)))

return v_x_global, v_y_global

# Method to close the Tkinter window

def close_window():

window.destroy()

def get_distance_btw_points(x1,y1,x2,y2):

"""

Calculate the distance between two points in feet.

@param x1: The x-coordinate of point 1

@param y1: The y-coordinate of point 1

@param x2: The x-coordinate of point 2

@param y2: The y-coordinate of point 2

@return distance: float: in feet

"""

distance = math.sqrt((x2-x1)**2 + (y2-y1)**2)

return distance

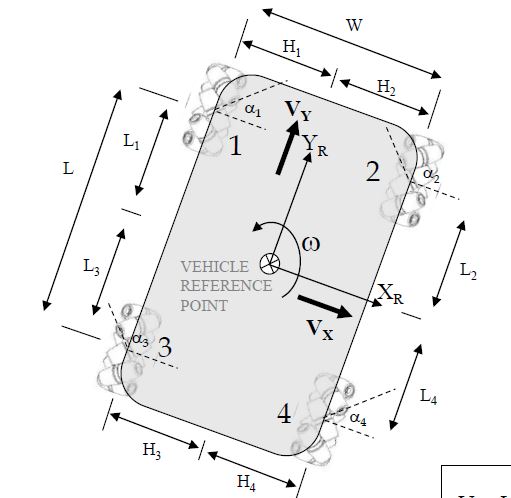

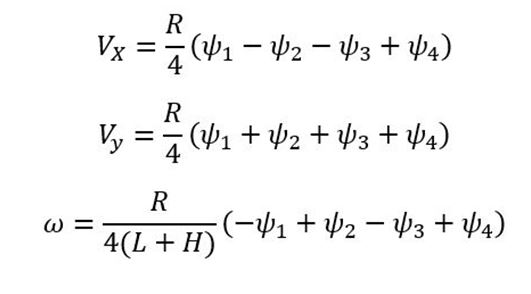

def get_robot_motion_values(rot1, rot2, rot3, rot4):

"""

Calculate the velocities in the x and y-directions in

the local reference frame as well as the rotation rate

of the vehicle reference point.

@param rot1: Rotation rate of wheel 1 in degrees/sec

@param rot2: Rotation rate of wheel 2 in degrees/sec

@param rot3: Rotation rate of wheel 3 in degrees/sec

@param rot4: Rotation rate of wheel 4 in degrees/sec

@return v_x_local float: Velocity in the x-direction

in the local reference frame in ft/s

@return v_y_local float: Velocity in the y-direction

in the local reference frame in ft/s

@return rotation_rate: Rotation rate of the vehicle

reference point in degrees per second in the

counter-clockwise direction

"""

v_x_local = (WHEEL_RADIUS/4) * (

rot1 - rot2 - rot3 + rot4)

v_y_local = (WHEEL_RADIUS/4) * (

rot1 + rot2 + rot3 + rot4)

rotation_rate = (WHEEL_RADIUS/(4*(

ROBOT_LENGTH + ROBOT_WIDTH)))*(

-rot1 + rot2 - rot3 + rot4)

return v_x_local, v_y_local, rotation_rate

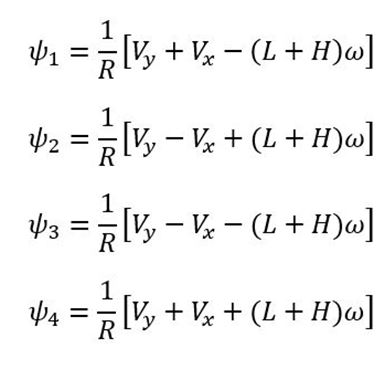

def get_wheel_rot_rates(v_x_local, v_y_local,

rotation_rate):

"""

Calculate the wheel rotation rates.

@param v_x_local: Velocity in the x-direction

in the local reference frame in ft/s

@param v_y_local: Velocity in the y-direction

in the local reference frame in ft/s

@param rotation_rate: Rotation rate in degrees per

second in the counter-clockwise direction (vehicle

reference point)

@return rot1, rot2, rot3, rot4: float: Wheel rotation

rates in degrees per second

"""

rot1 = (1/WHEEL_RADIUS)*(v_y_local + v_x_local - (

ROBOT_LENGTH + ROBOT_WIDTH) * rotation_rate)

rot2 = (1/WHEEL_RADIUS)*(v_y_local - v_x_local + (

ROBOT_LENGTH + ROBOT_WIDTH) * rotation_rate)

rot3 = (1/WHEEL_RADIUS)*(v_y_local - v_x_local - (

ROBOT_LENGTH + ROBOT_WIDTH) * rotation_rate)

rot4 = (1/WHEEL_RADIUS)*(v_y_local + v_x_local + (

ROBOT_LENGTH + ROBOT_WIDTH) * rotation_rate)

return rot1, rot2, rot3, rot4

def get_speed(distance, time):

"""

Calculate the speed of the vehicle using the distance

and time.

@param distance: The distance the robot vehicle must

travel between 2 or more points in feet

@param time: Total travel time in seconds

@return speed: float

"""

speed = distance / time

return speed

def get_velocity_magnitude(velocity_x, velocity_y):

"""

Calculate the speed of the vehicle using the x and y

components of the velocity.

@param velocity_x: Velocity in x-direction in ft/sec

@param velocity_y: Velocity in y-direction in ft/sec

@return speed: float

"""

speed = math.sqrt(((velocity_x)**2) + ((velocity_y)**2))

return speed

def is_close_to_edge(x, y):

"""

The viewable area will stay fixed until such time as

the vehicle reference point travels within 3 feet of

the viewable edge. Check if the viewable area needs to

be repositioned.

@param x: x-coordinate of the vehicle reference point

@param y: y-coordinate of the vehicle reference point

@return bool

"""

if (x - x_axis_max) > -BOUNDARY:

return True

elif (x - x_axis_min) < BOUNDARY:

return True

elif (y - y_axis_max) > -BOUNDARY:

return True

elif (y - y_axis_min) < BOUNDARY:

return True

else:

return False

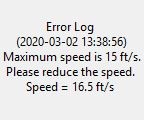

def is_too_fast(speed):

"""

The maximum speed of the robot vehicle is 15 ft/second

Check if the user input requires the vehicle to travel

faster than its maximum speed of 15 ft/second

@param speed: The magnitude of the velocity in ft/sec

@return bool

"""

if speed > 15.0:

return True

else:

return False

def plot_arrow(x, y, orientation):

"""

Plot the arrow on the top of the robot. Arrow points

to +y-direction of the robot (i.e. towards the front

center part of the robot). It is centered on the

vehicle reference point.

@param x: x-coordinate of the vehicle reference point

@param y: y-coordinate of the vehicle reference point

@param orientation: orientation of the vehicle

reference point in radians

"""

# Clear datapoints if they exist

try:

for datapoints in ax.get_lines():

datapoints.remove()

except:

pass

# Plot the arrow

plt.plot(x, y, marker=(3, 0, math.degrees(

orientation)), markersize=20, color="black")

def plot_grid(x, y):

"""

Plot the grid.

@param x: x-coordinate of the center of the grid.

@param y: y-coordinate of the center of the grid

"""

global x_axis_min, x_axis_max, y_axis_min, y_axis_max

# Set the x and y limits of the grid.

x_axis_max = x + (ENV_WIDTH / 2.0) + X_TICK_SPACING

x_axis_min = x - (ENV_WIDTH / 2.0)

y_axis_max = y + (ENV_LENGTH / 2.0) + Y_TICK_SPACING

y_axis_min = y - (ENV_LENGTH / 2.0)

ax.set(xlim=(x_axis_min, x_axis_max), ylim=(y_axis_min,

y_axis_max))

# Each square on the grid is 6inch by

# 6inch (6inch = 0.5 feet)

ax.set_xticks(np.arange(x_axis_min, x_axis_max,

X_TICK_SPACING))

ax.set_yticks(np.arange(y_axis_min, y_axis_max,

Y_TICK_SPACING))

ax.grid(True)

turn_off_tick_labels()

def plot_line(x1, y1, direction):

"""

Show the user defined path as a red line

@param x1: x-coordinate of the start point of the line

@param y1: y-coordinate of the start point of the line

@direction: Direction of travel of the vehicle

reference point in radians

"""

# Arbitrary-chosen line length

line_length = 2.0 * math.sqrt(2.0)

x2 = (line_length * math.cos(direction))

x2 = x1 + x2

y2 = (line_length * math.sin(direction))

y2 = y1 + y2

plt.plot([x1, x2], [y1, y2], color='red',

linestyle='-', linewidth=2)

def plot_path_traveled(x_values, y_values):

"""

Show the path traveled by the robot.

@param x_values list: List of x values

@param y_values list: List of y values

"""

plt.plot(x_values, y_values, color='green',

linestyle='-', linewidth=2)

def plot_robot(x, y, orientation):

"""

Plot the robot on the grid.

Rotate lower left coordinate of the robot based on

vehicle reference point's orientation.

This equation gives the lower left coordinate's new

position when rotated around the origin (x=0,y=0):

X = x*cos(θ) - y*sin(θ)

Y = x*sin(θ) + y*cos(θ)

@param x: x-coordinate of the vehicle reference point

@param y: y-coordinate of the vehicle reference point

@param orientation: orientation of the vehicle

reference point in radians

"""

global rect

# Remove the existing rectangle if it exists

try:

rect.remove()

except:

pass

rect_x_pos = ((-ROBOT_WIDTH/2.0) * math.cos(

orientation)) - ((-ROBOT_LENGTH/2.0) * math.sin(

orientation))

rect_y_pos = ((-ROBOT_WIDTH/2.0) * math.sin(

orientation)) + ((-ROBOT_LENGTH/2.0) * math.cos(

orientation))

# Translate lower left coordinate of the robot so it

# is relative to the vehicle reference point

rect_x_pos = rect_x_pos + x

rect_y_pos = rect_y_pos + y

# Update the robot's position and orientation

rect = patches.Rectangle((rect_x_pos,rect_y_pos),

ROBOT_WIDTH,ROBOT_LENGTH, math.degrees(

orientation),lw=3,ec='black', fc='orange')

# Add the rectangle to the Axes

ax.add_patch(rect)

def reset():

"""

This method resets the robot and grid to the origin

"""

global hist_x_vals, hist_y_vals

global x_pos_ref, y_pos_ref, vehicle_angle_ref

global circle1, this_rect

plot_grid(0,0)

plot_robot(0, 0, math.radians(0))

plot_arrow(0, 0, math.radians(0))

hist_x_vals.clear()

hist_y_vals.clear()

x_pos_ref = 0.0

y_pos_ref = 0.0

vehicle_angle_ref = 0.0

hist_x_vals.append(0)

hist_y_vals.append(0)

# Remove circle1 if it exists on the plot

try:

circle1.set_radius(0)

except:

pass

# Remove this_rect if it exists on the plot

try:

this_rect.remove()

except:

pass

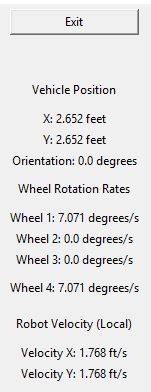

# Vehicle position display

veh_pos_label = tk.Label(window,

text = ("Vehicle Position"))

veh_pos_label.grid(row=2, column=4, padx=5)

# Add new position values to display window

veh_x_pos_label = tk.Label(window,

text = ("X: " + str(round(0.0,3)) + " feet"))

veh_x_pos_label.grid(row=3, column=4, padx=5)

veh_y_pos_label = tk.Label(window,

text = ("Y: " + str(round(0.0,3)) + " feet"))

veh_y_pos_label.grid(row=4, column=4, padx=5)

veh_orientation_label = tk.Label(window,

text = ("Orientation: " + str(

round(0.0,3)) + " degrees"))

veh_orientation_label.grid(row=5, column=4, padx=5)

# Wheel Rotation Rates display

wheel_rot_rates_label = tk.Label(window,

text = ("Wheel Rotation Rates"))

wheel_rot_rates_label.grid(row=6, column=4, padx=5)

# Add new rotation rates to display window

wheel_1_rot_label = tk.Label(window,

text = ("Wheel 1: " + str(round(0.0,3)) + " degrees/s"))

wheel_1_rot_label.grid(row=7, column=4, padx=5)

wheel_2_rot_label = tk.Label(window,

text = ("Wheel 2: " + str(round(0.0,3)) + " degrees/s"))

wheel_2_rot_label.grid(row=8, column=4, padx=5)

wheel_3_rot_label = tk.Label(window,

text = ("Wheel 3: " + str(round(0.0,3)) + " degrees/s"))

wheel_3_rot_label.grid(row=9, column=4, padx=5)

wheel_4_rot_label = tk.Label(window,

text = ("Wheel 4: " + str(round(0.0,3)) + " degrees/s"))

wheel_4_rot_label.grid(row=10, column=4, padx=5)

# Robot Velocity Display

robot_velocity_label = tk.Label(window,

text = ("Robot Velocity (Local)"))

robot_velocity_label.grid(row=11, column=4, padx=5)

robot_velocity_x_label = tk.Label(window,

text = ("Velocity X: " + str(round(0.0,3)) + " ft/s"))

robot_velocity_x_label.grid(row=12, column=4, padx=5)

robot_velocity_y_label = tk.Label(window,

text = ("Velocity Y: " + str(round(0.0,3)) + " ft/s"))

robot_velocity_y_label.grid(row=13, column=4, padx=5)

def stop():

"""

This method stops the current processes.

"""

global running_control_robot_body

global running_control_robot_wheels

running_control_robot_body = False

running_control_robot_wheels = False

def turn_off_tick_labels():

"""

Turn off the tick labels if desired.

"""

ax.set_yticklabels([])

ax.set_xticklabels([])

##################### Control Methods #####################

def start_control_robot_body():

"""

This method starts the control_robot_body method

"""

global running_control_robot_body

running_control_robot_body = True

def control_robot_body(direction = 45.0, speed = 2.5,

rotation_rate = 0.0):

"""

The user can specify the direction, speed, and rotation

rate of the vehicle reference point.

@param direction: The direction of the vehicle

reference point in degrees, measured from the

vehicle's positive x-axis

@param speed: The magnitude of the velocity in ft/sec

@param rotation_rate: Rotation rate in degrees/sec,

going in the counter-clockwise direction

"""

global hist_x_vals, hist_y_vals

global x_pos_ref, y_pos_ref, vehicle_angle_ref

if(running_control_robot_body):

# Time interval in seconds

dt = 0.25

# Method will not run if speed entered is >15 ft/s

if (is_too_fast(speed)):

# Error Messages

print("Error: Maximum speed is 15 " +

"ft/s.\nPlease increase the deadline.\n\n" +

"Speed = " + str(speed) + " ft/s")

error_label = tk.Label(window,

text = ("Error Log\n ("+ str(time.strftime(

"%Y-%m-%d %H:%M:%S", time.localtime(

))) + ")\n Maximum speed is 15 " +

"ft/s.\nPlease reduce the speed.\n" +

"Speed = " + str(speed) + " ft/s"))

error_label.grid(row=14, column=4,

padx=5, pady=25)

stop()

if(running_control_robot_body):

x_initial = x_pos_ref

y_initial = y_pos_ref

vehicle_angle_ref_initial = vehicle_angle_ref

# Convert direction (local) into direction (global)

direction_global = direction + vehicle_angle_ref

# Calculate velocity in the x-direction in the

# global reference frame

v_x_global = (speed) * math.cos(

math.radians(direction_global))

# Calculate velocity in the y-direction in the

# global reference frame

v_y_global = (speed) * math.sin(

math.radians(direction_global))

# Determine the new x-coordinate of the vehicle

# reference point

x_pos_ref = x_initial + (v_x_global * dt)

# Determine the new y-coordinate of the vehicle

# reference point

y_pos_ref = y_initial + (v_y_global * dt)

# Determine the new orientation of the vehicle

# reference point

vehicle_angle_ref = vehicle_angle_ref_initial + (

rotation_rate * dt)

# Reposition grid if we are close to the edge

if (is_close_to_edge(x_pos_ref, y_pos_ref)):

plot_grid(x_pos_ref, y_pos_ref)

# Update user-defined path

plot_line(x_initial,

y_initial, math.radians(direction_global))

plt.pause(dt)

# Move robot to new position

plot_robot(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

plot_arrow(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

# Update path traveled by robot

hist_x_vals.append(x_pos_ref)

hist_y_vals.append(y_pos_ref)

plot_path_traveled(hist_x_vals, hist_y_vals)

# Calculate velocity in the x-direction in the

# local reference frame

v_x_local = (speed) * math.cos(

math.radians(direction))

# Calculate velocity in the y-direction in the

# local reference frame

v_y_local = (speed) * math.sin(

math.radians(direction))

# Update wheel rotation rates

rot1, rot2, rot3, rot4 = get_wheel_rot_rates(

v_x_local, v_y_local, rotation_rate)

# Vehicle position display

print("VEHICLE POSITION")

print("X: " + str(x_pos_ref) + " feet")

print("Y: " + str(y_pos_ref) + " feet")

print("Orientation: " + str(vehicle_angle_ref) +

" degrees\n")

# Wheel rate display

print("WHEEL ROTATION RATES")

print("Wheel 1: " + str(rot1) + " degrees/s")

print("Wheel 2: " + str(rot2) + " degrees/s")

print("Wheel 3: " + str(rot3) + " degrees/s")

print("Wheel 4: " + str(rot4) + " degrees/s\n")

# Robot velocity display

print("ROBOT VELOCITY (LOCAL)")

print("V_X: " + str(v_x_local) + " ft/s")

print("V_Y: " + str(v_y_local) + " ft/s\n\n")

# Vehicle position display

veh_pos_label = tk.Label(window,

text = ("Vehicle Position"))

veh_pos_label.grid(row=2, column=4, padx=5)

# Add new position values to display window

veh_x_pos_label = tk.Label(window,

text = ("X: " + str(round(x_pos_ref,3)) + " feet"))

veh_x_pos_label.grid(row=3, column=4, padx=5)

veh_y_pos_label = tk.Label(window,

text = ("Y: " + str(round(y_pos_ref,3)) + " feet"))

veh_y_pos_label.grid(row=4, column=4, padx=5)

veh_orientation_label = tk.Label(window,

text = ("Orientation: " + str(

round(vehicle_angle_ref,3)) + " degrees"))

veh_orientation_label.grid(row=5, column=4, padx=5)

# Wheel Rotation Rates display

wheel_rot_rates_label = tk.Label(window,

text = ("Wheel Rotation Rates"))

wheel_rot_rates_label.grid(row=6, column=4, padx=5)

# Add new rotation rates to display window

wheel_1_rot_label = tk.Label(window,

text = ("Wheel 1: " + str(round(rot1,3)) + " degrees/s"))

wheel_1_rot_label.grid(row=7, column=4, padx=5)

wheel_2_rot_label = tk.Label(window,

text = ("Wheel 2: " + str(round(rot2,3)) + " degrees/s"))

wheel_2_rot_label.grid(row=8, column=4, padx=5)

wheel_3_rot_label = tk.Label(window,

text = ("Wheel 3: " + str(round(rot3,3)) + " degrees/s"))

wheel_3_rot_label.grid(row=9, column=4, padx=5)

wheel_4_rot_label = tk.Label(window,

text = ("Wheel 4: " + str(round(rot4,3)) + " degrees/s"))

wheel_4_rot_label.grid(row=10, column=4, padx=5)

# Robot Velocity Display

robot_velocity_label = tk.Label(window,

text = ("Robot Velocity (Local)"))

robot_velocity_label.grid(row=11, column=4, padx=5)

robot_velocity_x_label = tk.Label(window,

text = ("Velocity X: " + str(round(v_x_local,3)) + " ft/s"))

robot_velocity_x_label.grid(row=12, column=4, padx=5)

robot_velocity_y_label = tk.Label(window,

text = ("Velocity Y: " + str(round(v_y_local,3)) + " ft/s"))

robot_velocity_y_label.grid(row=13, column=4, padx=5)

plt.pause(dt)

window.after(1, lambda: control_robot_body(

float(direction_entry.get()),

float(speed_entry.get()),

float(rot_rate_entry.get())))

def start_control_robot_wheels():

"""

This method starts the control_robot_wheels method

"""

global running_control_robot_wheels

running_control_robot_wheels = True

def stop_control_robot_wheels(event):

"""

This method stops the control_robot_wheels process

upon either a mouse click on the plot or a

keyboard button push.

"""

global running_control_robot_wheels

running_control_robot_wheels = False

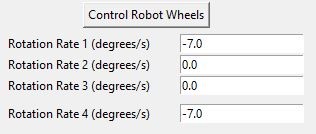

def control_robot_wheels(rot1 = -7.0, rot2 = 0.0,

rot3 = 0.0, rot4 = -7.0):

"""

The user shall be able to specify the rotation rate of

each wheel.

@param rot1: Rotation rate of wheel 1 in degrees/sec

@param rot2: Rotation rate of wheel 2 in degrees/sec

@param rot3: Rotation rate of wheel 3 in degrees/sec

@param rot4: Rotation rate of wheel 4 in degrees/sec

"""

global hist_x_vals, hist_y_vals

global x_pos_ref, y_pos_ref, vehicle_angle_ref

# In this mode alone, any mouse or keyboard button push

# will be considered a stop command.

# Must click directly on the plot.

fig.canvas.mpl_connect('button_press_event',

stop_control_robot_wheels)

fig.canvas.mpl_connect('key_press_event',

stop_control_robot_wheels)

if(running_control_robot_wheels):

# Time interval in seconds

dt = 0.25

# Get current robot motion

v_x_local, v_y_local, rotation_rate = (

get_robot_motion_values(rot1, rot2, rot3, rot4))

speed = get_velocity_magnitude(v_x_local, v_y_local)

# Method will not run if speed entered is >15 ft/s

if (is_too_fast(speed)):

# Error Messages

print("Error: Maximum speed is 15 " +

"ft/s.\nPlease increase the deadline.\n\n" +

"Speed = " + str(speed) + " ft/s")

error_label = tk.Label(window,

text = ("Error Log\n ("+ str(time.strftime(

"%Y-%m-%d %H:%M:%S", time.localtime(

))) + ")\n Maximum speed is 15 " +

"ft/s.\nPlease reduce the wheel rotation rates.\n" +

"Speed = " + str(speed) + " ft/s"))

error_label.grid(row=14, column=4,

padx=5, pady=25)

stop()

if(running_control_robot_wheels):

v_x_global, v_y_global = (

convert_local_velocity_to_global(

v_x_local, v_y_local))

# Calculate the direction of travel of the vehicle

# reference point

direction_global = math.degrees(math.atan2(

v_y_global,v_x_global))

x_initial = x_pos_ref

y_initial = y_pos_ref

vehicle_angle_ref_initial = vehicle_angle_ref

# Determine the new x-coordinate of the vehicle

# reference point

x_pos_ref = x_initial + (v_x_global * dt)

# Determine the new y-coordinate of the vehicle

# reference point

y_pos_ref = y_initial + (v_y_global * dt)

# Determine the new orientation of the vehicle

# reference point

vehicle_angle_ref = vehicle_angle_ref_initial + (

rotation_rate * dt)

# Reposition grid if we are close to the edge

if (is_close_to_edge(x_pos_ref, y_pos_ref)):

plot_grid(x_pos_ref, y_pos_ref)

# Update user-defined path

plot_line(x_initial, y_initial, math.radians(

direction_global))

plt.pause(dt)

# Move robot to new position

plot_robot(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

plot_arrow(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

# Update path traveled by robot

hist_x_vals.append(x_pos_ref)

hist_y_vals.append(y_pos_ref)

plot_path_traveled(hist_x_vals, hist_y_vals)

# Vehicle position display

print("VEHICLE POSITION")

print("X: " + str(x_pos_ref) + " feet")

print("Y: " + str(y_pos_ref) + " feet")

print("Orientation: " + str(vehicle_angle_ref) +

" degrees\n")

# Wheel rate display

print("WHEEL ROTATION RATES")

print("Wheel 1: " + str(rot1) + " degrees/s")

print("Wheel 2: " + str(rot2) + " degrees/s")

print("Wheel 3: " + str(rot3) + " degrees/s")

print("Wheel 4: " + str(rot4) + " degrees/s\n")

# Robot velocity display

print("ROBOT VELOCITY (LOCAL)")

print("V_X: " + str(v_x_local) + " ft/s")

print("V_Y: " + str(v_y_local) + " ft/s\n\n")

# Vehicle position display

veh_pos_label = tk.Label(window,

text = ("Vehicle Position"))

veh_pos_label.grid(row=2, column=4, padx=5)

# Add new position values to display window

veh_x_pos_label = tk.Label(window,

text = ("X: " + str(round(x_pos_ref,3)) + " feet"))

veh_x_pos_label.grid(row=3, column=4, padx=5)

veh_y_pos_label = tk.Label(window,

text = ("Y: " + str(round(y_pos_ref,3)) + " feet"))

veh_y_pos_label.grid(row=4, column=4, padx=5)

veh_orientation_label = tk.Label(window,

text = ("Orientation: " + str(

round(vehicle_angle_ref,3)) + " degrees"))

veh_orientation_label.grid(row=5, column=4, padx=5)

# Wheel Rotation Rates display

wheel_rot_rates_label = tk.Label(window,

text = ("Wheel Rotation Rates"))

wheel_rot_rates_label.grid(row=6, column=4, padx=5)

# Add new rotation rates to display window

wheel_1_rot_label = tk.Label(window,

text = ("Wheel 1: " + str(round(rot1,3)) + " degrees/s"))

wheel_1_rot_label.grid(row=7, column=4, padx=5)

wheel_2_rot_label = tk.Label(window,

text = ("Wheel 2: " + str(round(rot2,3)) + " degrees/s"))

wheel_2_rot_label.grid(row=8, column=4, padx=5)

wheel_3_rot_label = tk.Label(window,

text = ("Wheel 3: " + str(round(rot3,3)) + " degrees/s"))

wheel_3_rot_label.grid(row=9, column=4, padx=5)

wheel_4_rot_label = tk.Label(window,

text = ("Wheel 4: " + str(round(rot4,3)) + " degrees/s"))

wheel_4_rot_label.grid(row=10, column=4, padx=5)

# Robot Velocity Display

robot_velocity_label = tk.Label(window,

text = ("Robot Velocity (Local)"))

robot_velocity_label.grid(row=11, column=4, padx=5)

robot_velocity_x_label = tk.Label(window,

text = ("Velocity X: " + str(round(v_x_local,3)) + " ft/s"))

robot_velocity_x_label.grid(row=12, column=4, padx=5)

robot_velocity_y_label = tk.Label(window,

text = ("Velocity Y: " + str(round(v_y_local,3)) + " ft/s"))

robot_velocity_y_label.grid(row=13, column=4, padx=5)

plt.pause(dt)

window.after(1, lambda: control_robot_wheels(

float(rot_rate1_entry.get()),

float(rot_rate2_entry.get()),

float(rot_rate3_entry.get()),

float(rot_rate4_entry.get())))

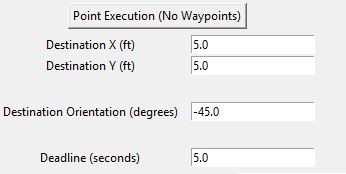

def point_execution_no_wp(x_final = 5.0, y_final = 5.0,

orientation_final = -45.0, deadline = 5.0):

"""

The user can specify a straight line path to an

end point, including a desired end orientation.

No waypoints between start and endpoints.

@param x_final: x-coordinate of the desired end point

@param y_final: y-coordinate of the desired end point

@param orientation_final: Desired end orientation in

degrees, going counter-clockwise from the x-axis

of the global reference frame

@param deadline: Time taken to get to end point in

seconds

"""

global hist_x_vals, hist_y_vals

global x_pos_ref, y_pos_ref, vehicle_angle_ref

distance = get_distance_btw_points(x_pos_ref,y_pos_ref,

x_final,y_final)

speed = get_speed(distance,deadline)

# Method will not run if speed entered is >15 ft/s

if (is_too_fast(speed)):

# Error Messages

print("Error: Maximum speed is 15 " +

"ft/s.\nPlease increase the deadline.\n\n" +

"Speed = " + str(speed) + " ft/s")

error_label = tk.Label(window,

text = ("Error Log\n ("+ str(time.strftime(

"%Y-%m-%d %H:%M:%S", time.localtime(

))) + ")\n Maximum speed is 15 " +

"ft/s.\nPlease increase the deadline.\n" +

"Speed = " + str(speed) + " ft/s"))

error_label.grid(row=14, column=4,

padx=5, pady=25)

stop()

# Calculate rotation rate in degrees/sec

rotation_rate = (orientation_final - (

vehicle_angle_ref))/(deadline)

# Number of frames to reach deadline

no_of_frames = 5

# Time interval in seconds

dt = (deadline / no_of_frames)

# Calculate the direction of travel of the vehicle

# reference point in degrees

direction_global = math.degrees(math.atan2(

(y_final - y_pos_ref),(x_final - x_pos_ref)))

# Plot user-defined path

plt.plot([x_pos_ref, x_final], [y_pos_ref, y_final],

color='red', linestyle='-', linewidth=2)

plt.pause(0.25)

# Calculate velocity in the x-direction in the

# global reference frame

v_x_global = (speed) * math.cos(

math.radians(direction_global))

# Calculate velocity in the y-direction in the

# global reference frame

v_y_global = (speed) * math.sin(

math.radians(direction_global))

for num in range(no_of_frames):

x_initial = x_pos_ref

y_initial = y_pos_ref

vehicle_angle_ref_initial = vehicle_angle_ref

# Determine the new x-coordinate of the vehicle

# reference point

x_pos_ref = x_initial + (v_x_global * dt)

# Determine the new y-coordinate of the vehicle

# reference point

y_pos_ref = y_initial + (v_y_global * dt)

# Determine the new orientation of the vehicle

# reference point

vehicle_angle_ref = vehicle_angle_ref_initial + (

rotation_rate * dt)

plt.pause(dt)

# Reposition grid if we are close to the edge

if (is_close_to_edge(x_pos_ref, y_pos_ref)):

plot_grid(x_pos_ref, y_pos_ref)

# Move robot to new position

plot_robot(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

plot_arrow(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

# Update path traveled by robot

hist_x_vals.append(x_pos_ref)

hist_y_vals.append(y_pos_ref)

plot_path_traveled(hist_x_vals, hist_y_vals)

# Convert direction (global) into direction (local)

direction = direction_global - vehicle_angle_ref

# Calculate velocity in the x-direction in the

# local reference frame

v_x_local = (speed) * math.cos(

math.radians(direction))

# Calculate velocity in the y-direction in the

# local reference frame

v_y_local = (speed) * math.sin(

math.radians(direction))

# Update wheel rotation rates

rot1, rot2, rot3, rot4 = get_wheel_rot_rates(

v_x_local, v_y_local, rotation_rate)

# Update user-defined path

plt.plot([x_pos_ref, x_final], [y_pos_ref,y_final],

color='red', linestyle='-', linewidth=2)

# Vehicle position display

print("VEHICLE POSITION")

print("X: " + str(x_pos_ref) + " feet")

print("Y: " + str(y_pos_ref) + " feet")

print("Orientation: " + str(vehicle_angle_ref) +

" degrees\n")

# Wheel rate display

print("WHEEL ROTATION RATES")

print("Wheel 1: " + str(rot1) + " degrees/s")

print("Wheel 2: " + str(rot2) + " degrees/s")

print("Wheel 3: " + str(rot3) + " degrees/s")

print("Wheel 4: " + str(rot4) + " degrees/s\n")

# Robot velocity display

print("ROBOT VELOCITY (LOCAL)")

print("V_X: " + str(v_x_local) + " ft/s")

print("V_Y: " + str(v_y_local) + " ft/s\n\n")

# Vehicle position display

veh_pos_label = tk.Label(window,

text = ("Vehicle Position"))

veh_pos_label.grid(row=2, column=4, padx=5)

# Add new position values to display window

veh_x_pos_label = tk.Label(window,

text = ("X: " + str(round(x_pos_ref,3)) + " feet"))

veh_x_pos_label.grid(row=3, column=4, padx=5)

veh_y_pos_label = tk.Label(window,

text = ("Y: " + str(round(y_pos_ref,3)) + " feet"))

veh_y_pos_label.grid(row=4, column=4, padx=5)

veh_orientation_label = tk.Label(window,

text = ("Orientation: " + str(

round(vehicle_angle_ref,3)) + " degrees"))

veh_orientation_label.grid(row=5, column=4, padx=5)

# Wheel Rotation Rates display

wheel_rot_rates_label = tk.Label(window,

text = ("Wheel Rotation Rates"))

wheel_rot_rates_label.grid(row=6, column=4, padx=5)

# Add new rotation rates to display window

wheel_1_rot_label = tk.Label(window,

text = ("Wheel 1: " + str(round(rot1,3)) + " degrees/s"))

wheel_1_rot_label.grid(row=7, column=4, padx=5)

wheel_2_rot_label = tk.Label(window,

text = ("Wheel 2: " + str(round(rot2,3)) + " degrees/s"))

wheel_2_rot_label.grid(row=8, column=4, padx=5)

wheel_3_rot_label = tk.Label(window,

text = ("Wheel 3: " + str(round(rot3,3)) + " degrees/s"))

wheel_3_rot_label.grid(row=9, column=4, padx=5)

wheel_4_rot_label = tk.Label(window,

text = ("Wheel 4: " + str(round(rot4,3)) + " degrees/s"))

wheel_4_rot_label.grid(row=10, column=4, padx=5)

# Robot Velocity Display

robot_velocity_label = tk.Label(window,

text = ("Robot Velocity (Local)"))

robot_velocity_label.grid(row=11, column=4, padx=5)

robot_velocity_x_label = tk.Label(window,

text = ("Velocity X: " + str(round(v_x_local,3)) + " ft/s"))

robot_velocity_x_label.grid(row=12, column=4, padx=5)

robot_velocity_y_label = tk.Label(window,

text = ("Velocity Y: " + str(round(v_y_local,3)) + " ft/s"))

robot_velocity_y_label.grid(row=13, column=4, padx=5)

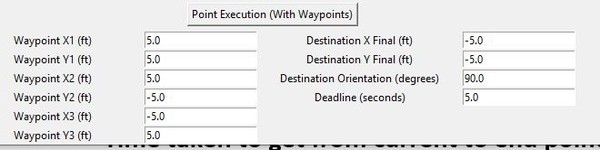

def point_execution_with_wp(x_wp1 = 5.0, y_wp1 = 5.0,

x_wp2 = 5.0, y_wp2 = -5.0,

x_wp3 = -5.0, y_wp3 = 5.0,

x_final = -5.0, y_final = -5.0,

orientation_final = 90.0, deadline = 5.0):

"""

The user can specify a straight line path to an

end point, including a desired end orientation.

Waypoints between start and endpoints can be specified.

@param x_wp1: x-coordinate of waypoint 1

@param y_wp1: y-coordinate of waypoint 1

@param x_wp2: x-coordinate of waypoint 2

@param y_wp2: y-coordinate of waypoint 2

@param x_wp3: x-coordinate of waypoint 3

@param y_wp3: y-coordinate of waypoint 3

@param x_final: x-coordinate of end point

@param y_final: y-coordinate of end point

@param orientation_final: Desired end orientation in

degrees.

@param deadline float: Time taken to get from current

point to end point in seconds.

"""

global hist_x_vals, hist_y_vals

global x_pos_ref, y_pos_ref, vehicle_angle_ref

# List of all x and y values along the path

x_list = [x_pos_ref, x_wp1, x_wp2, x_wp3, x_final]

y_list = [y_pos_ref, y_wp1, y_wp2, y_wp3, y_final]

# Number of legs on the path

no_of_legs = len(x_list) - 1

# Keep track of the distances of each leg of the trip

distance_list = []

# Calculate the distance of each leg of the trip in ft

for idx in range(no_of_legs):

distance_list.append(get_distance_btw_points(

x_list[idx],y_list[idx],x_list[idx + 1],y_list[

idx + 1]))

total_distance = sum(distance_list)

speed = get_speed(total_distance,deadline)

# Method will not run if speed entered is >15 ft/s

if (is_too_fast(speed)):

print("Error: Maximum speed is 15 " +

"ft/s.\nPlease increase the deadline.\n\n" +

"Speed = " + str(speed) + " ft/s")

error_label = tk.Label(window,

text = ("Error Log\n ("+ str(time.strftime(

"%Y-%m-%d %H:%M:%S", time.localtime(

))) + ")\n Maximum speed is 15 " +

"ft/s.\nPlease increase the deadline.\n" +

"Speed = " + str(speed) + " ft/s"))

error_label.grid(row=14, column=4,

padx=5, pady=25)

stop()

# Calculate rotation rate in degrees/sec

rotation_rate = (orientation_final - (

vehicle_angle_ref))/(deadline)

# Calculate the duration of each leg in seconds

deadline_list = []

for idx in range(no_of_legs):

deadline_list.append((distance_list[

idx]/total_distance) * deadline)

# Number of frames per leg

no_of_frames_per_leg = 5

# Time intervals in seconds for each leg

dt_list = []

for idx in range(no_of_legs):

dt_list.append(deadline_list[idx]/(

no_of_frames_per_leg))

# Move through each leg of the trip

for idx in range(no_of_legs):

# Number of frames per leg

no_of_frames_per_leg = 5

# Calculate the direction of travel of the vehicle

# reference point in degrees

direction_global = math.degrees(math.atan2(

(y_list[idx + 1] - y_list[idx]),(x_list[

idx + 1] - x_list[idx])))

# Calculate velocity in the x-direction in the

# global reference frame

v_x_global = (speed) * math.cos(

math.radians(direction_global))

# Calculate velocity in the y-direction in the

# global reference frame

v_y_global = (speed) * math.sin(

math.radians(direction_global))

for num in range(no_of_frames_per_leg):

x_initial = x_pos_ref

y_initial = y_pos_ref

vehicle_angle_ref_initial = vehicle_angle_ref

# Determine the new x-coordinate of the vehicle

# reference point

x_pos_ref = x_initial + (v_x_global * dt_list[

idx])

# Determine the new y-coordinate of the vehicle

# reference point

y_pos_ref = y_initial + (v_y_global * dt_list[

idx])

# Determine the new orientation of the vehicle

# reference point

vehicle_angle_ref = (

vehicle_angle_ref_initial + (

rotation_rate * dt_list[idx]))

# Reposition grid if we are close to the edge

if (is_close_to_edge(x_pos_ref, y_pos_ref)):

plot_grid(x_pos_ref, y_pos_ref)

# Move robot to new position

plot_robot(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

plot_arrow(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

# Update path traveled by robot

hist_x_vals.append(x_pos_ref)

hist_y_vals.append(y_pos_ref)

plot_path_traveled(hist_x_vals, hist_y_vals)

# Convert direction (global) into direction (local)

direction = direction_global - vehicle_angle_ref

# Calculate velocity in the x-direction in the

# local reference frame

v_x_local = (speed) * math.cos(

math.radians(direction))

# Calculate velocity in the y-direction in the

# local reference frame

v_y_local = (speed) * math.sin(

math.radians(direction))

# Update wheel rotation rates

rot1, rot2, rot3, rot4 = get_wheel_rot_rates(

v_x_local, v_y_local, rotation_rate)

# Vehicle position display

print("VEHICLE POSITION")

print("X: " + str(x_pos_ref) + " feet")

print("Y: " + str(y_pos_ref) + " feet")

print("Orientation: " + str(vehicle_angle_ref) +

" degrees\n")

# Wheel rate display

print("WHEEL ROTATION RATES")

print("Wheel 1: " + str(rot1) + " degrees/s")

print("Wheel 2: " + str(rot2) + " degrees/s")

print("Wheel 3: " + str(rot3) + " degrees/s")

print("Wheel 4: " + str(rot4) + " degrees/s\n")

# Robot velocity display

print("ROBOT VELOCITY (LOCAL)")

print("V_X: " + str(v_x_local) + " ft/s")

print("V_Y: " + str(v_y_local) + " ft/s\n\n")

# Vehicle position display

veh_pos_label = tk.Label(window,

text = ("Vehicle Position"))

veh_pos_label.grid(row=2, column=4, padx=5)

# Add new position values to display window

veh_x_pos_label = tk.Label(window,

text = ("X: " + str(round(x_pos_ref,3)) + " feet"))

veh_x_pos_label.grid(row=3, column=4, padx=5)

veh_y_pos_label = tk.Label(window,

text = ("Y: " + str(round(y_pos_ref,3)) + " feet"))

veh_y_pos_label.grid(row=4, column=4, padx=5)

veh_orientation_label = tk.Label(window,

text = ("Orientation: " + str(

round(vehicle_angle_ref,3)) + " degrees"))

veh_orientation_label.grid(row=5, column=4, padx=5)

# Wheel Rotation Rates display

wheel_rot_rates_label = tk.Label(window,

text = ("Wheel Rotation Rates"))

wheel_rot_rates_label.grid(row=6, column=4, padx=5)

# Add new rotation rates to display window

wheel_1_rot_label = tk.Label(window,

text = ("Wheel 1: " + str(round(rot1,3)) + " degrees/s"))

wheel_1_rot_label.grid(row=7, column=4, padx=5)

wheel_2_rot_label = tk.Label(window,

text = ("Wheel 2: " + str(round(rot2,3)) + " degrees/s"))

wheel_2_rot_label.grid(row=8, column=4, padx=5)

wheel_3_rot_label = tk.Label(window,

text = ("Wheel 3: " + str(round(rot3,3)) + " degrees/s"))

wheel_3_rot_label.grid(row=9, column=4, padx=5)

wheel_4_rot_label = tk.Label(window,

text = ("Wheel 4: " + str(round(rot4,3)) + " degrees/s"))

wheel_4_rot_label.grid(row=10, column=4, padx=5)

# Robot Velocity Display

robot_velocity_label = tk.Label(window,

text = ("Robot Velocity (Local)"))

robot_velocity_label.grid(row=11, column=4, padx=5)

robot_velocity_x_label = tk.Label(window,

text = ("Velocity X: " + str(round(v_x_local,3)) + " ft/s"))

robot_velocity_x_label.grid(row=12, column=4, padx=5)

robot_velocity_y_label = tk.Label(window,

text = ("Velocity Y: " + str(round(v_y_local,3)) + " ft/s"))

robot_velocity_y_label.grid(row=13, column=4, padx=5)

# Update user-defined path

plt.plot([x_pos_ref, x_list[idx + 1]], [

y_pos_ref,y_list[idx + 1]], color='red',

linestyle='-', linewidth=2)

plt.pause(dt_list[idx])

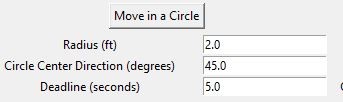

def move_in_a_circle(radius = 2.0, direction = 45.0,

deadline = 5.0):

"""

Vehicle can move in a circle with user-defined

radius and inclination (direction of circle center

from current vehicle position).

@param radius: Radius of the circle in feet

@param direction: Direction of circle center

from the vehicle reference point, measured

from the vehicle's positive x-axis in degrees

@param deadline float: Time taken to get from current

point to end point in seconds.

"""

global hist_x_vals, hist_y_vals

global x_pos_ref, y_pos_ref, vehicle_angle_ref

global circle1

# Rotation rate of vehicle reference point

rotation_rate = 0.0

# Convert direction (local) into direction (global)

direction_global = direction + vehicle_angle_ref

# x-coordinate of the center of the circle

x_center = x_pos_ref + (radius) * math.cos(

math.radians(direction_global))

# y-coordinate of the center of the circle

y_center = y_pos_ref + (radius) * math.sin(

math.radians(direction_global))

# Plot the circle path

circle1 = plt.Circle((x_center, y_center),

radius, color="red", fill=False, lw=2)

ax.add_artist(circle1)

# Record the angle at which the vehicle reference point

# is from the center of the circle in degrees

starting_angle = math.degrees(math.atan2((

y_pos_ref - y_center),(x_pos_ref - x_center)))

# Convert negative angles to positive angles

if starting_angle < 0:

starting_angle += 360

# Calculate the total distance of travel in feet

total_distance = 2 * math.pi * radius

speed = get_speed(total_distance,deadline)

# Method will not run if speed entered is >15 ft/s

if (is_too_fast(speed)):

print("Error: Maximum speed is 15 " +

"ft/s.\nPlease increase the deadline.\n\n" +

"Speed = " + str(speed) + " ft/s")

error_label = tk.Label(window,

text = ("Error Log\n ("+ str(time.strftime(

"%Y-%m-%d %H:%M:%S", time.localtime(

))) + ")\n Maximum speed is 15 " +

"ft/s.\nPlease increase the deadline.\n" +

"Speed = " + str(speed) + " ft/s"))

error_label.grid(row=14, column=4,

padx=5, pady=25)

stop()

# Number of individual movements along the circle path

no_of_circle_legs = 25

# Number of degrees per circle leg

no_of_degrees_per_circle_leg = 360.0/no_of_circle_legs

# Number of seconds per leg

dt = deadline/no_of_circle_legs

# Create a list of the angles at which the vehicle

# reference point is from the center of the circle

# for a complete circle path (in degrees)

angles_list = []

for angle_count in range(no_of_circle_legs):

starting_angle += no_of_degrees_per_circle_leg

angles_list.append(starting_angle)

# List of all x and y values along the path

x_list = [x_pos_ref]

y_list = [y_pos_ref]

for element in angles_list:

x_temp = radius * math.cos(math.radians(element))+ (

x_center)

y_temp = radius * math.sin(math.radians(element))+ (

y_center)

x_list.append(x_temp)

y_list.append(y_temp)

ax.add_artist(circle1)

plt.pause(dt)

# Move through each leg of the trip

for idx in range(no_of_circle_legs):

# Calculate the direction of travel of the vehicle

# reference point in degrees

direction_global = math.degrees(math.atan2(

(y_list[idx + 1] - y_list[idx]),(x_list[

idx + 1] - x_list[idx])))

# Calculate velocity in the x-direction in the

# global reference frame

v_x_global = (speed) * math.cos(

math.radians(direction_global))

# Calculate velocity in the y-direction in the

# global reference frame

v_y_global = (speed) * math.sin(

math.radians(direction_global))

x_initial = x_pos_ref

y_initial = y_pos_ref

vehicle_angle_ref_initial = vehicle_angle_ref

# Determine the new x-coordinate of the vehicle

# reference point

x_pos_ref = x_initial + (v_x_global * dt)

# Determine the new y-coordinate of the vehicle

# reference point

y_pos_ref = y_initial + (v_y_global * dt)

# Reposition grid if we are close to the edge

if (is_close_to_edge(x_pos_ref, y_pos_ref)):

plot_grid(x_pos_ref, y_pos_ref)

# Move robot to new position

plot_robot(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

plot_arrow(x_pos_ref,y_pos_ref,math.radians(

vehicle_angle_ref))

# Update path traveled by robot

hist_x_vals.append(x_pos_ref)

hist_y_vals.append(y_pos_ref)

plot_path_traveled(hist_x_vals, hist_y_vals)

# Convert direction (global) into direction (local)

direction = direction_global - vehicle_angle_ref

# Calculate velocity in the x-direction in the

# local reference frame

v_x_local = (speed) * math.cos(

math.radians(direction))

# Calculate velocity in the y-direction in the

# local reference frame

v_y_local = (speed) * math.sin(

math.radians(direction))

# Update wheel rotation rates

rot1, rot2, rot3, rot4 = get_wheel_rot_rates(

v_x_local, v_y_local, rotation_rate)

# Vehicle position display

print("VEHICLE POSITION")

print("X: " + str(x_pos_ref) + " feet")

print("Y: " + str(y_pos_ref) + " feet")

print("Orientation: " + str(vehicle_angle_ref) +

" degrees\n")

# Wheel rate display

print("WHEEL ROTATION RATES")

print("Wheel 1: " + str(rot1) + " degrees/s")

print("Wheel 2: " + str(rot2) + " degrees/s")

print("Wheel 3: " + str(rot3) + " degrees/s")

print("Wheel 4: " + str(rot4) + " degrees/s\n")

# Robot velocity display

print("ROBOT VELOCITY (LOCAL)")

print("V_X: " + str(v_x_local) + " ft/s")

print("V_Y: " + str(v_y_local) + " ft/s\n\n")

# Vehicle position display

veh_pos_label = tk.Label(window,

text = ("Vehicle Position"))

veh_pos_label.grid(row=2, column=4, padx=5)

# Add new position values to display window

veh_x_pos_label = tk.Label(window,

text = ("X: " + str(round(x_pos_ref,3)) + " feet"))

veh_x_pos_label.grid(row=3, column=4, padx=5)

veh_y_pos_label = tk.Label(window,

text = ("Y: " + str(round(y_pos_ref,3)) + " feet"))

veh_y_pos_label.grid(row=4, column=4, padx=5)

veh_orientation_label = tk.Label(window,

text = ("Orientation: " + str(

round(vehicle_angle_ref,3)) + " degrees"))

veh_orientation_label.grid(row=5, column=4, padx=5)

# Wheel Rotation Rates display

wheel_rot_rates_label = tk.Label(window,

text = ("Wheel Rotation Rates"))

wheel_rot_rates_label.grid(row=6, column=4, padx=5)

# Add new rotation rates to display window

wheel_1_rot_label = tk.Label(window,

text = ("Wheel 1: " + str(round(rot1,3)) + " degrees/s"))

wheel_1_rot_label.grid(row=7, column=4, padx=5)

wheel_2_rot_label = tk.Label(window,

text = ("Wheel 2: " + str(round(rot2,3)) + " degrees/s"))

wheel_2_rot_label.grid(row=8, column=4, padx=5)

wheel_3_rot_label = tk.Label(window,

text = ("Wheel 3: " + str(round(rot3,3)) + " degrees/s"))

wheel_3_rot_label.grid(row=9, column=4, padx=5)

wheel_4_rot_label = tk.Label(window,

text = ("Wheel 4: " + str(round(rot4,3)) + " degrees/s"))

wheel_4_rot_label.grid(row=10, column=4, padx=5)

# Robot Velocity Display

robot_velocity_label = tk.Label(window,

text = ("Robot Velocity (Local)"))

robot_velocity_label.grid(row=11, column=4, padx=5)

robot_velocity_x_label = tk.Label(window,

text = ("Velocity X: " + str(round(v_x_local,3)) + " ft/s"))

robot_velocity_x_label.grid(row=12, column=4, padx=5)

robot_velocity_y_label = tk.Label(window,

text = ("Velocity Y: " + str(round(v_y_local,3)) + " ft/s"))

robot_velocity_y_label.grid(row=13, column=4, padx=5)

plt.pause(dt)

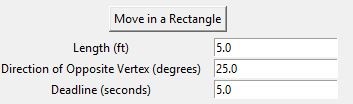

def move_in_a_rectangle(length_in_ft = 5.0,

direction_of_opp_vertex = 25.0, deadline = 5.0):

"""

Vehicle can move in a rectangle shape consisting of

user-defined side lengths and inclination (direction of

opposite vertex from current vehicle position). Vehicle

will start at the vertex.

@param length_in_ft: Length of the rectangle in feet

@param direction_of_opp_vertex: Direction of diagonally

opposite vertex from current vehicle position in

degrees, going counter-clockwise from the vehicle's

positive x-axis.

@param deadline float: Time taken to get from current

point to end point in seconds.

"""

global this_rect

# Get the length of the diagonal of the rectangle

diagonal_length = abs(length_in_ft/math.cos(

math.radians(direction_of_opp_vertex)))

# Get the width of the diagonal of the rectangle

width_in_ft = abs(diagonal_length * math.sin(

math.radians(direction_of_opp_vertex)))

# Convert direction (local) into direction (global)

direction_global = direction_of_opp_vertex + (

vehicle_angle_ref)

# Calculate the interior angle in degrees between

# diagonal of rectangle and the side length

interior_angle = math.degrees(math.acos(

length_in_ft/diagonal_length))

# Calculate coordinates for waypoint 1

x_wp1 = x_pos_ref + (length_in_ft * math.cos(

math.radians(direction_global - interior_angle)))

y_wp1 = y_pos_ref + (length_in_ft * math.sin(

math.radians(direction_global - interior_angle)))

# Calculate coordinates for waypoint 2

x_wp2 = x_pos_ref + (diagonal_length * math.cos(

math.radians(direction_global)))

y_wp2 = y_pos_ref + (diagonal_length * math.sin(

math.radians(direction_global)))

# Angle to wp3 as measured counter-clockwise from the

# global positive x-axis

wp3_angle = direction_global + (90.0-interior_angle)

# Calculate coordinates for waypoint 3

x_wp3 = x_pos_ref + (width_in_ft * math.cos(

math.radians(wp3_angle)))

y_wp3 = y_pos_ref + (width_in_ft * math.sin(

math.radians(wp3_angle)))

# Plot the rectangle

this_rect = patches.Rectangle((x_pos_ref,y_pos_ref),

length_in_ft,width_in_ft, direction_global - interior_angle,

lw=2,ec='red', fill=False)

# Add the rectangle to the Axes

ax.add_patch(this_rect)

point_execution_with_wp(x_wp1, y_wp1, x_wp2, y_wp2,

x_wp3, y_wp3, x_pos_ref, y_pos_ref, 0.0, deadline)

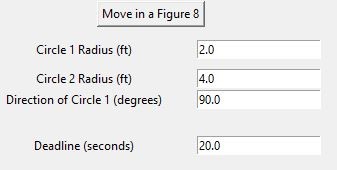

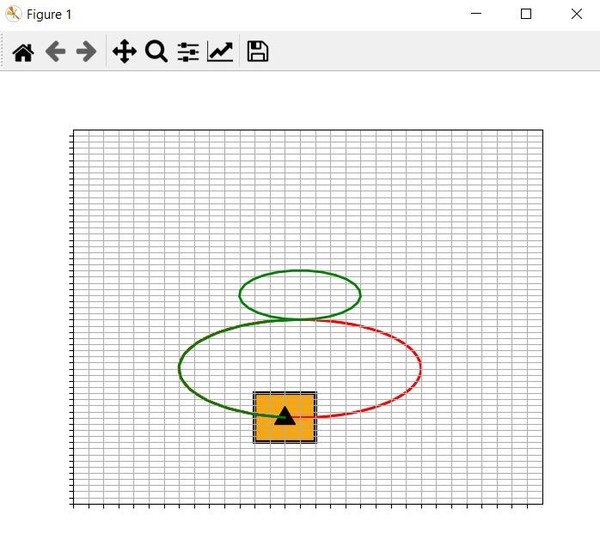

def move_in_a_figure_eight(circle1_radius = 2.0,

circle2_radius = 4.0, direction = 90.0,

deadline = 20.0):

"""

Vehicle can move in a figure 8 consisting of two

circles with two user-defined, possibly different

radii and inclination (direction of circle center

from current vehicle position).

@param circle1_radius: Radius of the 1st circle in feet

@param circle2_radius: Radius of the 2nd circle in feet

@param direction: Direction of circle1 center

from the vehicle reference point, measured

from the vehicle's positive x-axis in degrees

@param deadline float: Time taken to get from current

point to end point in seconds.

"""

# Set the deadlines for the completion of each circle

deadline1 = (circle1_radius/(

circle1_radius + circle2_radius)) * deadline

deadline2 = (circle2_radius/(

circle1_radius + circle2_radius)) * deadline

# Set the directions of each circle from the vehicle

# reference point

direction1 = direction

direction2 = direction + 180.0

# Move in a figure 8 pattern - 1st circle

move_in_a_circle(circle1_radius,direction1,deadline1)

# Clear out the first circle from the plot

circle1.set_radius(0)

# Move in a figure 8 pattern - 2nd circle

move_in_a_circle(circle2_radius,direction2,deadline2)

######################## Main Code ########################

# Initiate the simulation environment (i.e. grid)

plt.ion() # Turn on interactive mode

fig = plt.figure() # Create a new blank canvas

ax = fig.gca() # Get the current axes

reset()

####################### Tkinter GUI #######################

# Set the window title

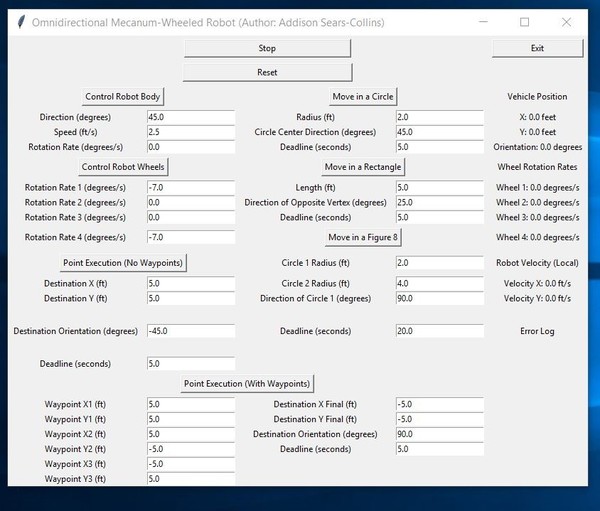

window.title("Omnidirectional Mecanum-Wheeled Robot " +

"(Author: Addison Sears-Collins)")

# Create user-interface

stop_button = tk.Button(window, text = "Stop", command=stop)

stop_button.grid(row=0, column=1, columnspan=2, pady=3,

ipadx=100)

reset_button = tk.Button(window, text = "Reset", command=reset)

reset_button.grid(row=1, column=1, columnspan=2, pady=3,

ipadx=100)

control_robot_body_button = tk.Button(window,

text = "Control Robot Body",

command=start_control_robot_body)

control_robot_body_button.grid(row=2, column=0,

columnspan=2, padx=5, pady=5)

window.after(1, lambda: control_robot_body(

float(direction_entry.get()),

float(speed_entry.get()),

float(rot_rate_entry.get())))

direction_label = tk.Label(window,

text = "Direction (degrees)")

direction_label.grid(row=3, column=0, padx=5)

direction_entry = tk.Entry(window)

direction_entry.grid(row=3, column=1, padx=5)

direction_entry.insert(0, 45.0)

speed_label = tk.Label(window, text = "Speed (ft/s)")

speed_label.grid(row=4, column=0, padx=5)

speed_entry = tk.Entry(window)

speed_entry.grid(row=4, column=1, padx=5)

speed_entry.insert(0, 2.5)

rot_rate_label = tk.Label(window,

text = "Rotation Rate (degrees/s)")

rot_rate_label.grid(row=5, column=0, padx=5)

rot_rate_entry = tk.Entry(window)

rot_rate_entry.grid(row=5, column=1, padx=5)

rot_rate_entry.insert(0, 0.0)

control_robot_wheels_button = tk.Button(window,

text = "Control Robot Wheels",

command=start_control_robot_wheels)

control_robot_wheels_button.grid(row=6, column=0,

columnspan=2, padx=5, pady=5)

window.after(1, lambda: control_robot_wheels(

float(rot_rate1_entry.get()),

float(rot_rate2_entry.get()),

float(rot_rate3_entry.get()),

float(rot_rate4_entry.get())))

rot_rate1_label = tk.Label(window,

text = "Rotation Rate 1 (degrees/s)")

rot_rate1_label.grid(row=7, column=0, padx=5)

rot_rate1_entry = tk.Entry(window)

rot_rate1_entry.grid(row=7, column=1, padx=5)

rot_rate1_entry.insert(0, -7.0)

rot_rate2_label = tk.Label(window,

text = "Rotation Rate 2 (degrees/s)")

rot_rate2_label.grid(row=8, column=0, padx=5)

rot_rate2_entry = tk.Entry(window)

rot_rate2_entry.grid(row=8, column=1, padx=5)

rot_rate2_entry.insert(0, 0.0)

rot_rate3_label = tk.Label(window,

text = "Rotation Rate 3 (degrees/s)")

rot_rate3_label.grid(row=9, column=0, padx=5)

rot_rate3_entry = tk.Entry(window)

rot_rate3_entry.grid(row=9, column=1, padx=5)

rot_rate3_entry.insert(0, 0.0)

rot_rate4_label = tk.Label(window,

text = "Rotation Rate 4 (degrees/s)")

rot_rate4_label.grid(row=10, column=0, padx=5)

rot_rate4_entry = tk.Entry(window)

rot_rate4_entry.grid(row=10, column=1, padx=5)

rot_rate4_entry.insert(0, -7.0)

point_exec_no_wp_button = tk.Button(window,

text = "Point Execution (No Waypoints)",

command=lambda: point_execution_no_wp(

float(destination_x_entry.get()),

float(destination_y_entry.get()),

float(destination_orientation_entry.get()),

float(deadline_entry.get())))

point_exec_no_wp_button.grid(row=11,

column=0, columnspan=2, padx=5, pady=5)

destination_x_label = tk.Label(window,

text = "Destination X (ft)")

destination_x_label.grid(row=12, column=0, padx=5)

destination_x_entry = tk.Entry(window)

destination_x_entry.grid(row=12, column=1, padx=5)

destination_x_entry.insert(0, 5.0)

destination_y_label = tk.Label(window,

text = "Destination Y (ft)")

destination_y_label.grid(row=13, column=0, padx=5)

destination_y_entry = tk.Entry(window)

destination_y_entry.grid(row=13, column=1, padx=5)

destination_y_entry.insert(0, 5.0)

destination_orientation_label = tk.Label(window,

text = "Destination Orientation (degrees)")

destination_orientation_label.grid(row=14, column=0,padx=5)

destination_orientation_entry = tk.Entry(window)

destination_orientation_entry.grid(row=14, column=1,padx=5)

destination_orientation_entry.insert(0, -45.0)

deadline_label = tk.Label(window,

text = "Deadline (seconds)")

deadline_label.grid(row=15, column=0, padx=5)

deadline_entry = tk.Entry(window)

deadline_entry.grid(row=15, column=1, padx=5)

deadline_entry.insert(0, 5.0)

point_exec_with_wp_button = tk.Button(window,

text = "Point Execution (With Waypoints)",

command=lambda: point_execution_with_wp(

float(wp_x1_entry.get()), float(wp_y1_entry.get()),

float(wp_x2_entry.get()), float(wp_y2_entry.get()),

float(wp_x3_entry.get()), float(wp_y3_entry.get()),

float(wp_xfinal_entry.get()), float(wp_yfinal_entry.get()),

float(destination_orientationwp_final_entry.get()),

float(deadlinewp_entry.get())))

point_exec_with_wp_button.grid(row=16, column=0,

columnspan=4, padx=5, pady=5)

wp_x1_label = tk.Label(window, text = "Waypoint X1 (ft)")

wp_x1_label.grid(row=17, column=0, padx=5)

wp_x1_entry = tk.Entry(window)

wp_x1_entry.grid(row=17, column=1, padx=5)

wp_x1_entry.insert(0, 5.0)

wp_y1_label = tk.Label(window, text = "Waypoint Y1 (ft)")

wp_y1_label.grid(row=18, column=0, padx=5)

wp_y1_entry = tk.Entry(window)

wp_y1_entry.grid(row=18, column=1, padx=5)

wp_y1_entry.insert(0, 5.0)

wp_x2_label = tk.Label(window, text = "Waypoint X2 (ft)")

wp_x2_label.grid(row=19, column=0, padx=5)

wp_x2_entry = tk.Entry(window)

wp_x2_entry.grid(row=19, column=1, padx=5)

wp_x2_entry.insert(0, 5.0)

wp_y2_label = tk.Label(window, text = "Waypoint Y2 (ft)")

wp_y2_label.grid(row=20, column=0, padx=5)

wp_y2_entry = tk.Entry(window)

wp_y2_entry.grid(row=20, column=1, padx=5)

wp_y2_entry.insert(0, -5.0)

wp_x3_label = tk.Label(window, text = "Waypoint X3 (ft)")

wp_x3_label.grid(row=21, column=0, padx=5)

wp_x3_entry = tk.Entry(window)

wp_x3_entry.grid(row=21, column=1, padx=5)

wp_x3_entry.insert(0, -5.0)

wp_y3_label = tk.Label(window, text = "Waypoint Y3 (ft)")

wp_y3_label.grid(row=22, column=0, padx=5)

wp_y3_entry = tk.Entry(window)

wp_y3_entry.grid(row=22, column=1, padx=5)

wp_y3_entry.insert(0, 5.0)

wp_xfinal_label = tk.Label(window,

text = "Destination X Final (ft)")

wp_xfinal_label.grid(row=17, column=2, padx=5)

wp_xfinal_entry = tk.Entry(window)

wp_xfinal_entry.grid(row=17, column=3, padx=5)

wp_xfinal_entry.insert(0, -5.0)

wp_yfinal_label = tk.Label(window,

text = "Destination Y Final (ft)")

wp_yfinal_label.grid(row=18, column=2, padx=5)

wp_yfinal_entry = tk.Entry(window)

wp_yfinal_entry.grid(row=18, column=3, padx=5)

wp_yfinal_entry.insert(0, -5.0)

destination_orientationwp_final_label = tk.Label(

window, text = "Destination Orientation (degrees)")

destination_orientationwp_final_label.grid(row=19,

column=2, padx=5)

destination_orientationwp_final_entry = tk.Entry(window)

destination_orientationwp_final_entry.grid(row=19,

column=3, padx=5)

destination_orientationwp_final_entry.insert(0, 90.0)

deadlinewp_label = tk.Label(window,

text = "Deadline (seconds)")

deadlinewp_label.grid(row=20, column=2, padx=5)

deadlinewp_entry = tk.Entry(window)

deadlinewp_entry.grid(row=20, column=3, padx=5)

deadlinewp_entry.insert(0, 5.0)

move_in_a_circle_button = tk.Button(window, text = "Move in a Circle",

command=lambda: move_in_a_circle(

float(radius_entry.get()),

float(cir_direction_entry.get()),

float(cir_deadline_entry.get())))

move_in_a_circle_button.grid(row=2, column=2, columnspan=2, padx=5, pady=5)

radius_label = tk.Label(window, text = "Radius (ft)")

radius_label.grid(row=3, column=2, padx=5)

radius_entry = tk.Entry(window)

radius_entry.grid(row=3, column=3, padx=5)

radius_entry.insert(0, 2.0)

cir_direction_label = tk.Label(window, text = "Circle Center Direction (degrees)")

cir_direction_label.grid(row=4, column=2, padx=5)

cir_direction_entry = tk.Entry(window)

cir_direction_entry.grid(row=4, column=3, padx=5)

cir_direction_entry.insert(0, 45.0)

cir_deadline_label = tk.Label(window, text = "Deadline (seconds)")

cir_deadline_label.grid(row=5, column=2, padx=5)

cir_deadline_entry = tk.Entry(window)

cir_deadline_entry.grid(row=5, column=3, padx=5)

cir_deadline_entry.insert(0, 5.0)

move_in_a_rectangle_button = tk.Button(window,

text = "Move in a Rectangle",

command=lambda: move_in_a_rectangle(

float(length_entry.get()),

float(direc_opp_vrtx_entry.get()),

float(rect_deadline_entry.get())))

move_in_a_rectangle_button.grid(row=6, column=2, columnspan=2, padx=5, pady=5)

length_label = tk.Label(window, text = "Length (ft)")

length_label.grid(row=7, column=2, padx=5)

length_entry = tk.Entry(window)

length_entry.grid(row=7, column=3, padx=5)

length_entry.insert(0, 5.0)

direc_opp_vrtx_label = tk.Label(window, text = "Direction of Opposite Vertex (degrees)")

direc_opp_vrtx_label.grid(row=8, column=2, padx=5)

direc_opp_vrtx_entry = tk.Entry(window)

direc_opp_vrtx_entry.grid(row=8, column=3, padx=5)

direc_opp_vrtx_entry.insert(0, 25.0)

rect_deadline_label = tk.Label(window, text = "Deadline (seconds)")

rect_deadline_label.grid(row=9, column=2, padx=5)

rect_deadline_entry = tk.Entry(window)

rect_deadline_entry.grid(row=9, column=3, padx=5)

rect_deadline_entry.insert(0, 5.0)

fig8_button = tk.Button(window,

text = "Move in a Figure 8",

command=lambda: move_in_a_figure_eight(

float(circle1_radius_entry.get()),

float(circle2_radius_entry.get()),

float(direction_circle1_entry.get()),

float(fig_8_deadline_entry.get())))

fig8_button.grid(row=10, column=2, columnspan=2, padx=5, pady=5)

circle1_radius_label = tk.Label(window, text = "Circle 1 Radius (ft)")

circle1_radius_label.grid(row=11, column=2, padx=5)

circle1_radius_entry = tk.Entry(window)

circle1_radius_entry.grid(row=11, column=3, padx=5)

circle1_radius_entry.insert(0, 2.0)

circle2_radius_label = tk.Label(window, text = "Circle 2 Radius (ft)")

circle2_radius_label.grid(row=12, column=2, padx=5)

circle2_radius_entry = tk.Entry(window)

circle2_radius_entry.grid(row=12, column=3, padx=5)

circle2_radius_entry.insert(0, 4.0)

direction_circle1_label = tk.Label(window, text = "Direction of Circle 1 (degrees)")

direction_circle1_label.grid(row=13, column=2, padx=5)

direction_circle1_entry = tk.Entry(window)

direction_circle1_entry.grid(row=13, column=3, padx=5)

direction_circle1_entry.insert(0, 90.0)

fig_8_deadline_label = tk.Label(window, text = "Deadline (seconds)")

fig_8_deadline_label.grid(row=14, column=2, padx=5)

fig_8_deadline_entry = tk.Entry(window)

fig_8_deadline_entry.grid(row=14, column=3, padx=5)

fig_8_deadline_entry.insert(0, 20.0)

# Vehicle Position Display

veh_pos_label = tk.Label(window,

text = ("Vehicle Position"))

veh_pos_label.grid(row=2, column=4, padx=5)

veh_x_pos_label = tk.Label(window,

text = ("X: " + "0.0" + " feet"))

veh_x_pos_label.grid(row=3, column=4, padx=5)

veh_y_pos_label = tk.Label(window,

text = ("Y: " + "0.0" + " feet"))

veh_y_pos_label.grid(row=4, column=4, padx=5)

veh_orientation_label = tk.Label(window,

text = ("Orientation: " + "0.0" + " degrees"))

veh_orientation_label.grid(row=5, column=4, padx=5)

# Wheel Rotation Rates display

wheel_rot_rates_label = tk.Label(window,

text = ("Wheel Rotation Rates"))

wheel_rot_rates_label.grid(row=6, column=4, padx=5)

# Add new rotation rates to display window

wheel_1_rot_label = tk.Label(window,

text = ("Wheel 1: " + "0.0" + " degrees/s"))

wheel_1_rot_label.grid(row=7, column=4, padx=5)

wheel_2_rot_label = tk.Label(window,

text = ("Wheel 2: " + "0.0" + " degrees/s"))

wheel_2_rot_label.grid(row=8, column=4, padx=5)

wheel_3_rot_label = tk.Label(window,

text = ("Wheel 3: " + "0.0" + " degrees/s"))

wheel_3_rot_label.grid(row=9, column=4, padx=5)

wheel_4_rot_label = tk.Label(window,

text = ("Wheel 4: " + "0.0" + " degrees/s"))

wheel_4_rot_label.grid(row=10, column=4, padx=5)

# Robot Velocity Display

robot_velocity_label = tk.Label(window,

text = ("Robot Velocity (Local)"))

robot_velocity_label.grid(row=11, column=4, padx=5)

robot_velocity_x_label = tk.Label(window,

text = ("Velocity X: " + "0.0" + " ft/s"))

robot_velocity_x_label.grid(row=12, column=4, padx=5)

robot_velocity_y_label = tk.Label(window,

text = ("Velocity Y: " + "0.0" + " ft/s"))

robot_velocity_y_label.grid(row=13, column=4, padx=5)

# Error Messages

error_label = tk.Label(window,

text = ("Error Log"))

error_label.grid(row=14, column=4,

padx=5, pady=25)

# Quit button

exit_button = tk.Button(window, text = "Exit",

command=close_window)

exit_button.grid(row=0, column=4, columnspan=2,

padx=5, pady=5, ipadx=50)

window.mainloop()